-40%

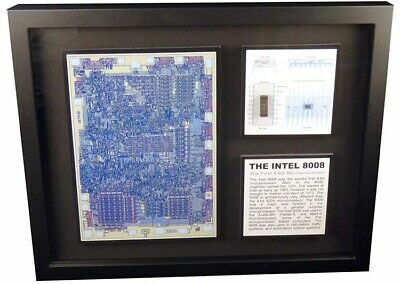

The Intel 8008 - The World's First 8-bit Microprocessor

$ 174.23

- Description

- Size Guide

Description

About this Artwork:This artwork is a mixed media display celebrating the Intel 8008. Work on the 8008, originally named the 1201, first started at Intel as early as 1969, however it was not brought to market until April of 1972. This artwork includes 3 major items. It has a large image of an Intel 8080 chip. On the back is a narrative describing the artwork and the 8008, and the artist’s signature. Also, included is an Intel 8008 chip in a 16 lead DIP (Dual Inline Package) package. The new-old-stock, fully functional chip is mounted with threads and is surrounded by an enlarged diagram of the chip with the electrical signal designations for each of its leads.

Framing:

The artwork is framed in an 11"x14" black shadow box frame, with glass. All framing materials are acid free. A narrative about the artwork that includes the artist’s signature is placed on the back of the artwork.

Production:

Limited by availability of wafers and chips.

Shipping:

I ship by US Priority Mail, shipping is actual cost.

Want to see more ChipScapes?

Click here to see more ChipScapes

TM

in my store on eBay

About Making Computer Chips:

Computer chips start out as ordinary sand, which is silicon dioxide. However, the silicon must be made very, very pure. The first step is to melt the sand, in a furnace that reaches about 3200

o

F, and mix with carbon. This first purification process creates 99% pure Silicon, a common output is Silicon Carbide. The Silicon Carbide is processed in a trichlorosilane distillation method to create 99.9999% pure silicon called polycrystalline silicon. The polysilicon is broken up into chunks. These chunks are melted in a crucible at about 2500

o

F. A silicon crystal seed is dipped in molten silicon and slowly drawn out to create a cylinder of silicon. These silicon cylinders are some of the purest crystals on the planet. Once the silicon cylinder is grown to the desired diameter, it is sawed into wafers. These wafers are polished to achieve a very flat mirror surface. Transistors, and other micro-electronic parts, are built on the polished wafer in layers in a process called etching. The wafer is then sawed into its individual chips. Each chip is mounted in an electronic package that serves to protect it and connect it to the outside world. It has been said that computer chips are the greatest value added product in the world. We essentially take a pile of sand and change it into thousands of dollars worth of computer chips.

General Information:

These artworks are the creation of

ChipScapes

TM

artist Steve Emery.

ChipScapes

TM

are photographs taken of computer chips, boards, and other computer artifacts. They are sort of chip landscapes, or

ChipScapes

TM

for short. Most often a macro-lens or microscope is used with special lightning to achieve these unique artworks.

Intel, IBM, Fairchild, DEC, Signetics, Intersil, AMD, Zilog, Motorola, MOS, NEC, Texas Instruments, are some of the great chip making companies. Chips like the Intel 4004, MOS 6502, Zilog Z80, AMD 2901, IBM PowerPC and others have changed the way people work and play.

ChipScapes

TM

are dedicated to preserving and sharing these computing and communication technologies that changed the world.

ChipScapes

TM

artworks are fine collectible artworks.

ChipScapes

TM

come is a variety of shapes sizes and colors. Clusters of my artwork make for stunning displays! A

ChipScape

TM

would make a great gift for the nerd, geek, engineer, programmer, IT executive, or just that technology savvy person in your life.

More Questions?

For more information about ChipScapes

TM

, please check out my ChipScapes

TM

website.